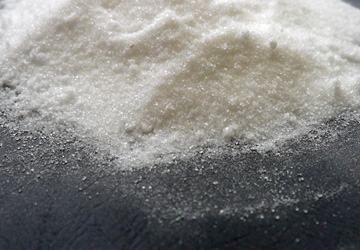

Development of zirconium production at the Chepetsk Mechanical Plant

- home

- Clients

- Results of our work

- Development of zirconium production at the Chepetsk Mechanical Plant

Development of zirconium production at the Chepetsk Mechanical Plant

Zirconium market research completed by Industrial Information Agency in June 2010

Research materials in detailwhether:

- reserves and production of mineral zirconium-containing raw materials in the world,

- state of field development in Russia,

- offer metal zirconium on the world market,

- production volumes by manufacturers,

- distribution of demand for zirconium and segments,

- price dynamics for zirconium sponge,

- volumes and prospects of non-nuclear consumption of zirconium,

- identification 30 consumers of zirconium.

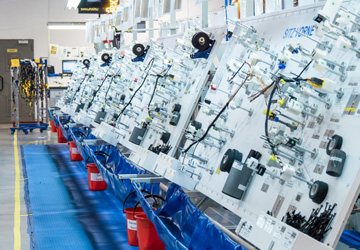

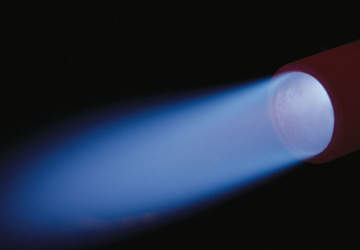

In 2010 at the ChMP chlorination site, the design capacity of the line was achieved

in the amount of 1000 tons per year for zirconium.

At the absorption treatment unit of the separation unit for zirconium and hafnium chlorides

an intermediate suitable for obtaining a zirconium sponge.

For the period from 2009 to March 2011, 30 units of new equipment were introduced into the technology.

In 2011 the production of zirconium sponge according to the technological scheme through zirconium dioxide was mastered.

For the purpose of organizing sales zirconium on a commercial basis:

• production of an additional qualifying batch of pressure pipes for Canadian reactors has been completed

CANDU to complete the qualification process, pipes shipped to the customer

• internal batches of TREX-pipe blanks from Zirkaloy-2 alloy were manufactured and controlled

according to the schemes "forging-rolling" and "rolling-rolling" for GNF-A & GE Canada

• a demonstration batch of clad pipes made of Zirkaloy-4 alloy was made and sent to the Korean side.

In 2012:

- industrial batches of pure zirconium sponge from zirconium dioxide were obtained,

- Manufacture of E110 alloy cladding pipes for VVER reactors has been transferred to the flowsheet

using new equipment

- work continued on the introduction of chloride technology for the production of zirconium sponge

- the creation of a pilot plant for the production of zirconium dioxide has begun.

On June 13, 2013 ChMP was awarded the status of a qualified supplier with the right to participate in the tender for the execution of reactor orders for CANDU programs.

The significance of this event cannot be overestimated –

The USSR and Russia have never supplied components and fuel elements for North American equipment.

ChMP opened up the possibility of supplying zirconium pipes to a large and interesting market:

status "qualified supplier" gives CMP the right to participate in the tender,

what is important in terms of developing production competencies.

In 2013:

- received confirmation of JSC "TVEL" about the extension of the order of technological channels,

- the first batches of TVS-KVADRAT components for JSC NZHK,

- work on the transition to a new technological scheme for rolling has been completed

- continued work on the introduction of chloride technology for the production of zirconium sponge,

- a new scheme production of pipes and bars,

- production technology has been worked out and pilot batches of granulated zirconium dioxide have been obtained.

Update date: 09/12/2016

Feedback

company's news

Study of the global and Russian markets of additive packages

Research of the market of mining dump trucks and loaders

Market research of ammonium sulfate and complex mineral fertilizers

Work on the report "Market research of ammonium sulfate and complex mineral fertilizers" has been completed.

Research of the market of forging and pressing equipment

Study of the Russian coated paper market

Work on the report "Study of the Russian coated paper market" has been completed.

Research of the Russian markets of toluene and vinyl acetate

Work on the report "Research of the Russian markets of toluene and vinyl acetate" has been completed.

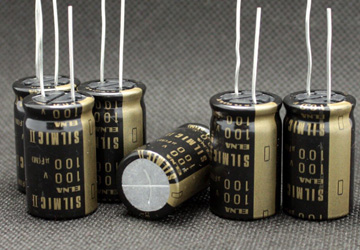

Assessment of customer satisfaction and brand awareness of electrical products

Work on the report "Assessment of customer satisfaction and brand awareness of electrical products" has been completed.

Study of the Russian market of electrocast refractories and raw materials

Work on the report "Study of the Russian market of electrocast refractories and raw materials" has been completed.

Selection of suppliers of tri-n-hexylaluminum in friendly countries that have not imposed sanctions

Work on the report "Selection of suppliers of tri-n-hexylaluminum in friendly countries that have not imposed sanctions" has been completed.

Study of the Russian and global market of sorbic acid and potassium sorbate

Work on the report "Study of the Russian and global market of sorbic acid and potassium sorbate" has been completed.

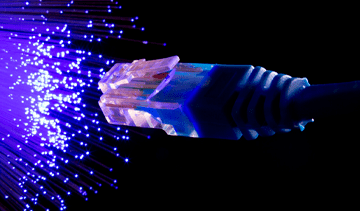

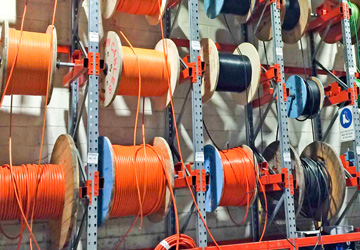

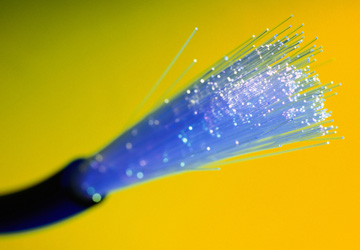

Research of the Russian optical fiber market in 2022

Work on the report "Research of the Russian optical fiber market in 2022" has been completed.

Bioprotein Market Research (Methane Fermented Feed Protein)

Study of the Russian energy market, coniferous timber and waste paper markets

Work on the report "Study of the Russian energy market, coniferous timber and waste paper markets" has been completed.

Research of the Uzbek market of rolled metal products and grinding balls

Work on the report "Research of the Uzbek market of rolled metal products and grinding balls" has been completed.

Research of the global and Russian market of tank containers for liquid hydrogen

Coated paper price monitoring

Work on the report "Coated paper price monitoring" has been completed.

Analysis of Brazilian commodity deliveries to Russia

Work on the report "Analysis of Brazilian commodity deliveries to Russia" has been completed.

Research of the single-sided coated paperboard market in the Russian Federation

Marketing research of the naphthenic oils market

Examination of the market price of a complex of equipment for the acceptance and processing of grapes with a capacity of 900 tons per day

Examination of the market price of a complex of equipment for the acceptance and processing of grapes with a capacity of 900 tons per day

Study of the Russian Market of Pure Vanadium Pentoxide

Assessment of the capacity of the Russian market of brazed heat exchangers

Supplier selection of tertiary dodecylmercaptan, ethylenediamine, N-butyl chloride, chromium 2-ethylhexanoate...

Suppliers of tertiary dodecylmercaptan, ethylenediamine, N-butyl chloride, chromium 2-ethylhexanoate have been selected...

Assessment of the potential of import substitution of coal for hookahs

Marketing research of the glass medical container market

Research of the Russian market of fuel and hookah charcoal briquettes

Study of the Russian and world market conditions for urea-ammonia mixture

Uzbekistan market research on mill lining and crusher armor

The work on the report "Uzbekistan market research on mill lining and crusher armor" has been completed.

Competitor analysis of psychological support services

Study of the conjuncture of freight traffic from Turkey to Russia

Marketing research of the market of electric motors, frequency converters and geared motors

Search for manufacturers and suppliers of polylactide fibers in Russia or in non-sanctioned (friendly) countries

Search for manufacturers and suppliers of polylactide fibers in Russia or non-sanctioned (friendly) countries

Marketing research of the Russian and global MRI market

Search for manufacturers and suppliers of the required products in Russia or in non-sanctioned (friendly) countries

In the face of possible restrictions on the supply of used reagents, Sibur is taking anti-risk measures...

Analysis of the Russian white oils market

Work on the report "Analysis of the Russian white oils market" has been completed.

API in the TOP-10 companies in the category "Consulting in the field of marketing and PR"

Research of the Russian market of ion-exchange resins

Research of the conjuncture of the Russian market of metal and non-metal lockers

The key task of the study was to assess the capacity of the locker market, including in terms of material (metal, chipboard, MDF, plastic/HPL composite)

Assessment of the import substitution potential of printed circuits in Russia

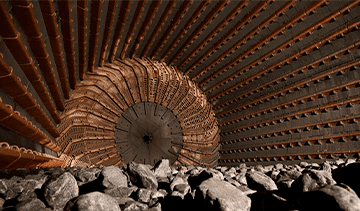

Mining equipment market research

Investigation of the conjuncture of the Russian market of compounds of metals and elements

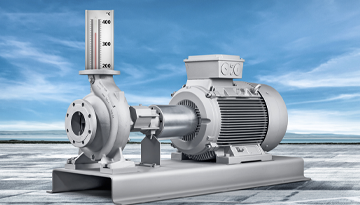

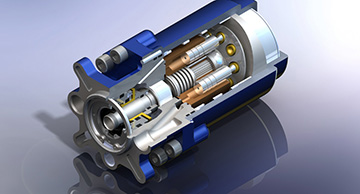

Marketing research of russian pumps production in 2021

Estimated volume of plywood production in Russia

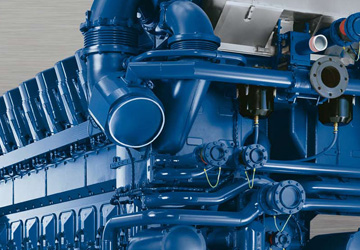

Market research DGU / DES / GPU and engines for DGU and GPU with a power of 800 kW

Research of the Russian market of organic and organomineral fertilizers

Research of the conjuncture of the Russian and world market of MMA and PMMA

Completed a study of the Russian and world market conditions for MMA and PMMA

Study of the Russian Market of Reagents for Dust Suppression and Antifreeze

Study of the Russian market of reagents for dust suppression and antifreeze has been completed

Research of the russian market of ammonium fluoride, sodium fluoride, and potassium fluoride

The work on the report "Research of the russian market of ammonium fluoride, sodium fluoride, and potassium fluoride"

State of the coated paper market in Kazakhstan and Uzbekistan, 2020

Report on the state of the coated paper market in the Russian Federation for 2020 and forecast for 2021

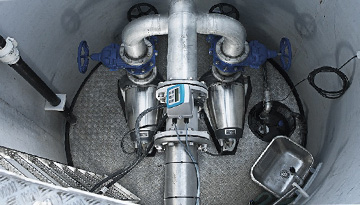

Marketing research of sewage pumping stations

Research of the Russian market conditions MHUK

Market research of abrasive grain (electrocorundum)

Market research of the glass medical containers

Research of the Russian market for tableware made of opal glass

Plans for changes in power generation capacities in Russia

Research of the Russian Market of Solid Caustic Soda

Formate market research (with a focus on sodium formate)

Market research for gas piston engines (power range 140-1000 kW)

Research of the Russian market of manufacturers of sleeves assemblies

Market Research for Cryogenic Temperature Testing

Mining equipment market research

Study of the situation in the Russian carbon dioxide market

API in the TOP-10 companies in the category "Consulting in the field of marketing and PR"

Market research for hollow metal structures

Battery market research in selected countries

Investigation of the conjuncture of the Russian market of ortho-phosphoric acid

Study of the conjuncture of the Russian market of PTFE products

Skif-M company dossier

Research of the Russian Market of Reciprocating Compressors

Research of the conjuncture of the Russian market of medical equipment

Marketing research of the Russian market of supercapacitors

Assessment of the prospects and profitability of the agreed zones and the development of proposals for the creation of new ones within the sports and cultural complex

Research of the Russian market of emulsion PVC

Market research of liquid pyrolysis products fraction

Identification of investment projects for the production of plywood

Selection of partners in Russia for Japanese companies

Research of the conjuncture of the Russian market of frequency converters for individual segments

Market research of lithium batteries in Russia

Marketing research of the market conditions for glass insulators for power transmission lines

Research of the conjuncture of the Russian market of stamped products

Research of the Russian market of oversized tires and oversized tire services

Marketing research of the conjuncture of the Russian market of caterpillar transporters

We are working

Research of the Russian market of equipment for the mining industry

Marketing research of the metal-cutting tool market for 2019

Marketing research of the market of caustic and chlorine-containing products

Research of the Russian market of caustic soda

Industrial Information Agency in TOP-5

Marketing research of the containerboard market

Marketing research of the hydrogen market in the Russian Federation

Marketing research of business opportunities for Swiss suppliers in the Russian market of oil and gas engineering

Marketing research of the wireless sensors market

Marketing research of the chlorine market in Russia and the CIS

Russian Defense Industry Summit

Marketing research of the rosin ester market

Overview of franchising in Russia

Market analysis of high-viscosity white technical oils, specialty isoparaffin oils and edible paraffins

Market Analysis for High Viscosity White Industrial Oils, Specialty Isoparaffin Oils and Edible Paraffins

Accreditation from the Russian Export Center

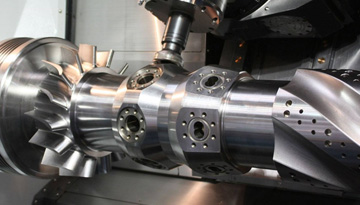

Analysis of the Russian metalworking equipment market

Work on the report "Analysis of the Russian metalworking equipment market" has been completed.

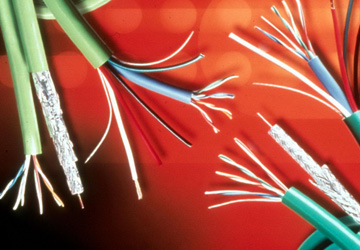

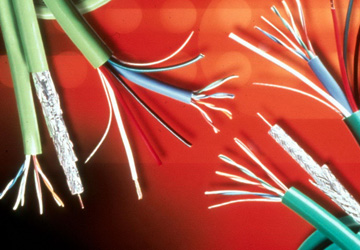

Identification of promising types of cable products from foreign manufacturers

Identification of promising types of cable products from foreign manufacturers that are in demand on the Russian market

Identification of promising types of cable products from foreign manufacturers that are in demand on the Russian market

Analysis of potential directions of development of the designed gas-chemical complex

Marketing research of the diesel engine market 110-550 hp

Rating of the 200 largest construction companies in the oil and gas sector

Rating of the 200 largest construction companies in the oil and gas sector

Marketing research of the ferrous metallurgy market

Marketing research of the market of diesel engines up to 30 kW and equipment based on them

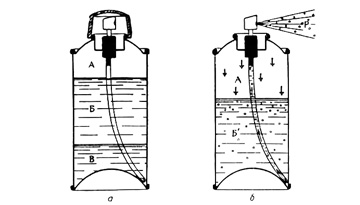

Marketing research of the market of automatic fire extinguishing systems

Report on the state of the coated paper market in the Russian Federation for 2018 and forecast for 2019

Assessment of brand awareness and customer loyalty in the Russian coated paper market

Marketing research of the signaling market

Marketing research of the industrial market of the Russian Federation and the market of large offices

Search for distributors in Belarus

API in the rating of RA Expert

Analysis and development prospects of the Russian component base: axial piston, gear hydraulic pumps and motors; hydrodistributors

Marketing research of the diesel, gas-piston, gas-diesel engines market

Marketing research gas piston engines

Analysis and prospects for the development of the Russian component base: axial-piston, gear hydraulic pumps and motors; directional control valves

Market research of feed phosphates in Russia and CIS countries

Study of the feed phosphate market in Russia and CIS countries

Analysis of imports of carbide metal-cutting tools for 2018 in the Russian Federation

Analysis of imports of carbide metal-cutting tools in Russia in 2018

Marketing research: Rationale for investment in the construction of an LNG plant

Marketing research of the Russian fiber market for 2018

Marketing research of the Russian fiber market for 2018

Marketing research of the market of automatic fire extinguishing systems

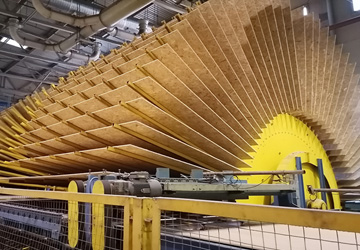

Marketing research to assess the prospects and sales potential of wood-fiber boards on a phenol-free binder.

Marketing research of the potassium nitrate market

Potassium nitrate market research

Accreditation by ROSNEFT

Analysis of deliveries of foreign-made tractors of the studied range to the Russian market from non-CIS countries and CIS countries

Marketing research of vegetable oil market in Russia and Ukraine

Marketing research of the polyethylene market

Assessment of the needs of the FEFD market in liquid nitrogen and liquid oxygen

Assessment of the market needs of the Far Eastern Federal District in liquid nitrogen and liquid oxygen

Marketing research of the arugula market

Marketing research of the market of electrical components and power equipment

Marketing research of the glass fiber braided wire market

Monitoring paper prices and their changes

Preparation of the marketing part of the feasibility study of a plant for the production of high-precision steel castings

Market research of the well filters market for the oil and gas industry

Marketing research of the market of wires: extra-flexible and with plunger insulation

Marketing research of the equipment market for oil and gas production

Marketing research of the electricity meters market

Marketing research: pump production volume in 2017

Marketing research: organization of production of industrial paint and varnish materials in Kazakhstan

Finding suppliers: Raised floor based on calcium sulfate

Market Research: Coated Paper Market Size and Forecast

Assessing brand awareness and customer loyalty

Marketing research: import of electric motors to Kazakhstan

Research of the Russian market of aluminum composite panels

Research of the Russian market of products made of glass, aluminum profiles and alucobond

Market research for glass, aluminum profile and alucobond products

Marketing research of the lubricants market in the oil and gas industry

Marketing research: import and export of RF fiber optic cable in 2014-2018

Research of the Russian market of used petroleum oils

Marketing research of the secondary polypropylene market

Market research for hydrocarbon gases

Results of the statutory audit

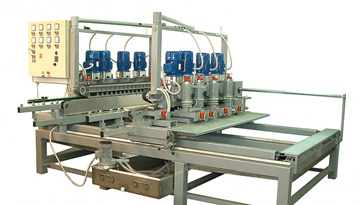

Marketing research of the glass processing equipment market

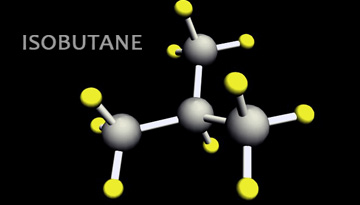

Marketing research of the market of isobutane, propellant in the Russian Federation

Marketing research of the market of diesel generator sets (DGU) and gas piston units (GPU)

Overview of the market of aluminum hydroxides and oxides of non-metallurgical grades

Report review

Updating the study in 8 industries

Marketing research of the market of replicated fiberglass products

Marketing research of the metal-cutting tool market for 2017

Marketing research of the printing equipment market

Marketing research of the Russian market of frequency converters

Marketing research of the car service market

Marketing research of the crushed stone market of Kazakhstan

Marketing research of the Russian-made metalworking tool market

Marketing research of the Russian MDI market

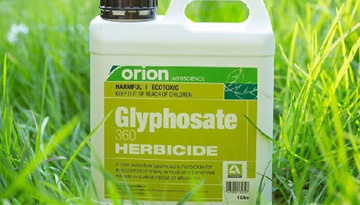

Glyphosate and 2,4 D-acid production technology licensors

Marketing research of the market of 2,4 D-acid and glyphosate in the Russian Federation.

Marketing research of the market for 4 types of equipment

Development of a feasibility study for the modernization of the production of liquefied hydrocarbon gases (LPG) (propane, butane, SPBT, ethane) for the Russian and European markets.

Overview of chicken manure processing technologies

Research of the Kazakhstan market of lining of crushers and grinding equipment

Offer of foreign-made metalworking tools

Research of the Russian market of molybdenum-containing granules

Research of the Russian market of explosion-proof cable glands

Marketing research of the woodworking equipment market

Research of the industrial cleaning market in the Moscow region

Research of the Russian market of testing services and laboratory services

Database of potential customers among enterprises with technological operations for stamping or drawing

Study of pipeline valves and actuators

Conjuncture of supply of foreign-made products on the Russian market of pipeline valves and actuators

The market of cleaning products for industrial use

Industrial Cleaning Market Research

Database of participants in the Russian ecosystem of innovations, technologies and startups.

Competitor analysis: Houghton and Quaker Chemicals.

Market of high alumina products

Research of the Russian market of high alumina products

Marketing research of the furniture and components market for 2016

Analysis of prices for motor oils in various distribution channels

Analysis of prices for motor oils in various distribution channels (wholesale, retail, interner stores, service stations)

Study of the Russian market of refractories

Research on the Russian refractory market

Marketing research of the traffic control market conditions

Analysis of production volumes of pumps, disinfection/decontamination plants

Marketing research of the food market in the Russian Federation

Monitoring the state of development of a competitor - Trianon.

Study of the Russian carbon dioxide market

Research on the Russian carbon dioxide market

Study of brand awareness and assessment of loyalty in the market of electrical products

Studying brand awareness and evaluating loyalty in the electrical products market

Research of the Russian market of turning parts

Research on the Russian market for turning parts

Study of the Russian carbon dioxide market

Research on the Russian carbon dioxide market

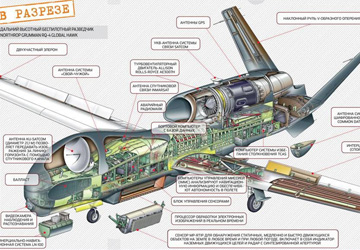

UAV research

Research unmanned aerial vehicle market

API in the TOP-10 companies in the category "Consulting in the field of marketing and PR"

API in "TOP-10" Russian companies based on 2016 in the category "Marketing and PR consulting"

Completed a study of the market of catalysts for the production of polyethylene

Polyethylene catalyst market research

Chemical industry

An overview of the industry "chemical industry".

Overview of the "building materials" industry

Overview of the building materials industry

Overview of the machine tool industry

Overview of the machine tool industry.

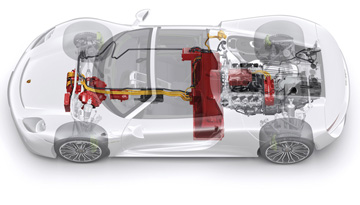

Automotive industry overview

An overview of the automotive industry.

Petroleum engineering

Completed work on the overview of the industry "petroleum engineering"

Aviation industry overview

An overview of the aviation industry.

Information and computer technology

An overview of the "information and computer technology" industry.

Food industry and mechanical engineering

Overview of the "food and engineering" industry.

Overview of the industry "shipbuilding"

An overview of the "shipbuilding" industry.

Overview of the industry "light industry"

Overview of the "light industry" industry

Pharmaceutical industry overview

Overview of the "pharmaceuticals" industry.

Provision of information services for the preparation of a list of target enterprises

Marketing research of production, import and export of cables, wires and equipment

Marketing research of the traffic control market conditions

Marketing research of the market conditions for forgings

Prospects for development and potential for import substitution in industrial sectors

Development prospects and import substitution potential in industrial sectors

Study of the state and development of key civilian sectors of the Russian economy

Research on the state and development of key civilian sectors of the Russian economy

Completed study of the market of motor oils

Motor Oil Market Research

Market of personal mobile electric transport

Personal mobile electric transport market

Accounting services market research

Accounting services market research

Analysis of the conjuncture of the supply of foreign-made metalworking tools on the Russian market

Analysis of the conjuncture of the supply of foreign-made metalworking tools on the Russian market

Research of the equipment market for sawmills in Russia

Sawmill equipment market research in Russia

Carbide market research

Research on the Russian market for carbide tools

Study of import substitution of steel or iron castings and cast parts

Study of import substitution of steel or iron castings and cast parts

Research of the Russian encoder market

Russian encoder market research

Study of the Russian hydrochloric acid market

Market research for linings for mills and crushing equipment

Research on the Russian market for linings for mills and crushing equipment

Happy New Year!

Happy New Year!

Market Research for Magnetoresistive Sensors

Research of the Russian market of magnetoresistive sensors

Research of the Russian market of tableted salt

Research on the Russian tableted salt market.

Research of the Russian market of pumping and fire stations.

Completed a study of the Russian market of pumping and fire stations.

Import analysis of pumping equipment

Research of the Russian market of paints and varnishes for furniture

Study of the Russian market of paints and varnishes for furniture and wood products

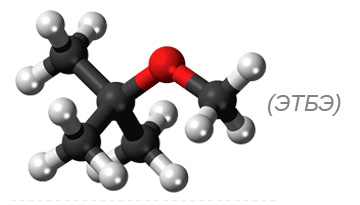

Study of the Russian market of ethyl tertiary butyl ether (ETBE)

Russian Ethyl Tertiary Butyl Ether (ETBE) Market Study Completed

Research of the industrial gases market in the Far Eastern Federal District

Research of the industrial gases market in the Far Eastern Federal District

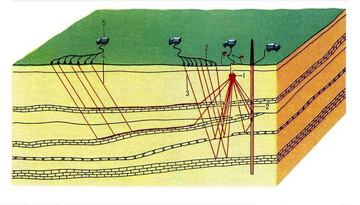

Seismic vibration sources market research

Study of the Russian market of seismic sources

Hydrochloric Acid Market Research

Research on the Russian hydrochloric acid market

Marketing research of the construction market

Research of the Russian market of silicate lumps and liquid glass

Research of the Russian market of silicate lumps and liquid glass has been completed.

Study of the Russian market of sour crude oil, fuel oil, straight-run gasoline, marine fuel oil and gas oil.

Completed market research for sour crude, fuel oil, straight-run gasoline, marine fuel oil and gas oil.

Research of the market of semiprecious products

Research on the market for gem products, including emeralds, alexandrites, beryls, chrysoberyls, phenakites, as well as phlogopite and muscovite

Research of the Russian market of normal butane, maleic anhydride, benzene, FZhPP and NGL.

Review of the Russian market of normal butane, maleic anhydride, benzene, FZHPP and NGL.

Research of the Russian market of products of processing and use of methane.

Research on the Russian market for methane processing and use products.

Marketing research of woodworking equipment

Marketing research of agricultural machines

Marketing research of the frozen bread market

Biofuel market research

Research on the Russian biofuel market.

Marketing research of Russian companies (manufacturers) working in the field of food products for children

Marketing research of the furniture and component goods market

Marketing research of food products

Research of the global and Russian startup market (Startup).

Research of the global and Russian startup market (Startup) has been completed.

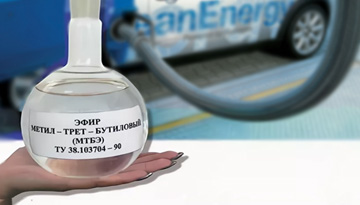

Methyl Tertiary Butyl Ether (MTBE) Market Research

Research on the Russian market of methyl tertiary butyl ether (MTBE)

Research of the Russian market of crushing and screening equipment

Research of the Russian crushing and screening equipment market completed.

Research of the Russian market of circular grinding machines.

Completed a study of the Russian market of circular grinding machines.

Methanol market research

Russian methanol market research

Research of the Russian market of baddeleyite-corundum refractories.

Research of the Russian market of baddeleyite-corundum refractories completed.

UAV market

Unmanned aerial vehicle (UAV) market research completed.

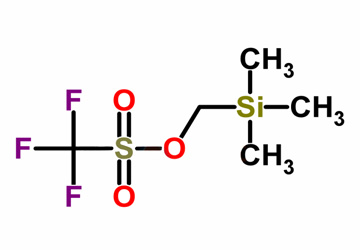

Research of the Russian market of organosilicon compounds

Study of the Russian market of organosilicon compounds.

Study of Russian pump manufacturers

Study of Russian pump manufacturers completed.

Research of the Russian market of a mirror cloth

Research of the Russian market of mirror fabrics has been completed.

Research of the Russian and Kazakhstan market of service of oversized tires.

Research of the Russian and Kazakhstan market of service of large tires is completed.

Research of the mobile cellular market in the context of the development of MVNO (virtual cellular operator).

Completed a study of the mobile cellular marketin the context of the development of MVNO (virtual mobile operator).

Study of the Russian market of ethyl mercaptan (odorants)

Completed a study of the Russian market of ethyl mercaptan (odorants).

Heads of significant networks for the sale of motor fuels.

Identification of relevant contacts of the leaders of significant networks for the sale of motor fuels.

Ferric chloride market research

Completed research on the ferric chloride market.

Hydrochloric Acid Market Research

Hydrochloric acid market research completed.

Aluminum Polyoxychloride Market Research

Aluminum polyoxychloride market research completed.

Market research of calcium chloride

Completed a study of calcium chloride market.

Market research of sodium chloride (sodium salt)

Sodium chloride sodium chloride (sodium salt) market research completed.

Market research of caustic soda

Analysis of the caustic soda market has been completed.

Chlorine market research.

Chlorine market research completed.

Market research of a mixture of calcium chloride and sodium chloride

Market research a mixture of calcium chloride and sodium chloride.

Market research for high power diesel engines.

High Power Diesel Market Study Completed.

Market Research for Wear Resistant Carbide Tools

Completed market research for wear-resistant carbide tools.

selection of European start-ups for application in the automotive industry

Selection of European start-ups for application in the automotive industry completed

Market research of electric wheels and personal electric vehicles

Market research on electric wheels and personal electric vehicles

Assessment of the import substitution potential of the steel and iron casting market

Assessing the import substitution potential of the steel and iron casting market

Research of the Russian market of herbicides, including Cletodim

Study of the Russian market of herbicides, including Cletodym.

Market research of recycled granulated polypropylene

Recycled granulated polypropylene market research completed

Research of the Russian market of PVC products

Research of the Russian market of PVC products

source materials for the preparation of a report on the leather industry in Russia

Input materials for preparing a report on the leather industry in Russia

Research for FSUE Goznak.

Research completed for FSUE Goznak.

Research of the world market of high-temperature current sources

High-Temperature Power Supply Global Market Study Completed

Import substitution potential of lecithin

Potential for import substitution of lecithin, including those containing phosphatidylcholine.

Research of the Russian market of modifying additives for asphalt concrete

Completed a study of the Russian market of modifying additives for asphalt concrete.

Market research of hydrocarbons - LPG, BGS, NGL

Completed a study of the hydrocarbon market - LPG, BGS, NGL.

API in the register of qualified contractors VEB

"Vnesheconombank" November 10, 2015 included us in the register of qualified contractors for marketing research with a rating of 81.2 points out of 100 maximum.

Marketing research of the Russian laminated paper market

IPA assistance in the conference "Italia Restarts Up"

IPA contributed to attracting Russian venture companies to the conference.....

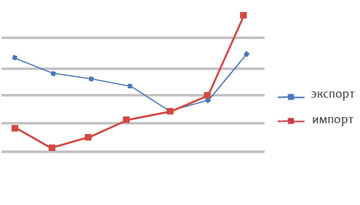

Export/import analysis: woodworking machines

Research of the Russian and world base oil market

Research of Russian and global base oil markets completed.

Database of potential customers for design and engineering calculations.

Database of potential customers for design and engineering calculations.

API Analysts Reveal Market Scale for Oil-Free Screw Compressors

Completed a study of the Russian market for oil-free screw compressors.

Export/import analysis: agricultural machinery

Optical fiber market research

The first optical fiber plant in Russia

Marketing research: Transportation in Russia

Market research for liquefied hydrocarbon gases

Liquefied petroleum gas market study completed...

Analysis of export / import of food products, incl. baby food separately

Analysis of export/import market of curtains, curtains

Structural Graphite and Shaped Products Market

Competitive environment in the market of structural graphite and shaped products.

Marketing research: Information about the financial and economic activities of enterprises

Glyphosate Market Research

Glyphosate market research completed.

Sunflower and sunflower oil market

Market research sunflower and sunflower oil.

Market research of equipment for the production of autowires

The main driver of the change in demand for auto harnesses is a feature of the industrial assembly of foreign cars....

Cable market research

Cable market research helped secure funding.

Hydrogen Peroxide Market Research

Hydrogen peroxide market research completed.

Prospects for the mine hoist market in the API study

The scale of production by Russian manufacturers has been clarified and the potential for import substitution has been assessed.

Research of the Russian quartz sand market

Research of the Russian quartz sand market completed

Market for halogen-free compounds

The market for halogen-free compositions in Russia has shown continuous growth over the past few years and reached 9 thousand tons in 2014.

Update of the finished research: Marketing research of the quartz sand market

Marketing research: Non-container trucking with Europe

Export/import analysis of earthmoving machines

Fuel cell market

Average annual growth of the fuel cell market by 2020 will be 49.1%.

Research of the wheat market in the Rostov region

Completed work on the study of the wheat market of the Rostov region.

Research of the Russian market of dimethyl disulphide

Russian dimethyl disulphide market study completed

Import/Export Analysis of Glass Processing Machinery

Market research of wear-resistant carbide tools.

2014 wear-resistant carbide tool market research completed.

Marketing Research: Container Shipping

Research of the Russian and world battery market

Research of the Russian and global battery market completed.

Research of the Russian market of benzene.

Study of the Russian benzene market completed.

Accreditation by OAO NK Rosneft

Industrial Information Agency has been accredited by OAO "NK"Rosneft"

Research of the Russian market of halogen-free non-flammable compounds HFFR

Research on the Russian market for halogen-free, non-flammable HFFR compounds has been completed.

Export/import analysis of marble and stone processing equipment

Promising groups of equipment for deliveries to Russia. Selection of potential partners

Research of the world market of potassium chloride

Potassium chloride global market research completed.

Footwear export/import analysis

Sberbank 2015

JSC "Sberbank of Russia" entrusted us with research in 2015.

Research of the Russian and world market of iron oxide pigments

Research of the Russian and global iron oxide pigment market has been completed.

World demand for catalysts by 2020 may reach 7.8 million tons

Global demand for catalysts may reach 7.8 million tons by 2020.

Analysis of export/import of packaging equipment, incl. equipment for the production of aerosol cans

Study of the Russian market of white carbon (silicon dioxide)

Study of the Russian white carbon (silicon dioxide) market completed.

Study of the demand for potatoes among food industry enterprises.

Studying demand for potatoes in the food industry.

Study of the Russian market for technical research and testing

Technical research and testing market study completed.

Research of the Russian and world market of industrial catalysts

Research of Russian and global industrial catalysts market completed.

Research of the Russian market of benzene, sulfuric acid, caustic soda, liquid sulfur.

Completed the study of the Russian market of benzene, sulfuric acid, caustic soda, liquid sulfur.

Research to identify contact persons who make decisions on the purchase of professional cleaning products for industrial enterprises.

Identification of contact persons who make purchasing decisions professional industrial cleaning products.

Marketing research of the LED and energy-saving lamps market.

Research of the Russian market of paints and varnishes

Completed a study of the Russian market of paints and varnishes for railway rolling stock and for industrial woodworking.

Marketing research of the world market of small-capacity single-cylinder diesel engines

Marketing research: Quarterly results of electronic trading

Updating information on the market of potash fertilizers.

Updating information on the potash fertilizer market has been completed.

Market research for OSB production equipment.

Completed market research for OSB production equipment.

Research of the Russian butane market

Russian butane market study completed.

Analysis of export / import of agricultural machinery, ceramic products, furniture accessories

Research for Vnesheconombank

Since 2013 we have been conducting research in the interests of Vnesheconombank.

Research of the Russian methanol market.

Russian methanol market study completed.

Research of the Russian market of grinding equipment.

Research of the Russian grinding equipment market completed.

Marketing research of the market of welding machines: robotic and semi-automatic machines

Research of the Russian market of aluminum parts and castings for the automotive industry

Completed a study of the Russian market of aluminum parts and castings for the automotive industry (autocomponents).

Export/import analysis of leather processing equipment

Research of the Russian market of engineering services in the field of energy saving, energy efficiency, automation and IT

Completed a study of the Russian market of engineering services in the field of energy saving, energy efficiency, automation and IT.

Marketing research of the Russian market of reciprocating compressors

API director on Russia 24 channel

Petrov A.V. acted as an expert on industrial policy for the Urban Technologies program.

Research of the Russian market of air separation plants.

Study of the Russian market for air separation units has been completed.

Marketing research of the market situation of magnesian binders

Statistics for 2013 for 2 countries

Statistics for 2013 for the following countries: Taiwan, Vietnam, Thailand, Indonesia, Singapore

Marketing research of high power electric motors in the segment of the largest metallurgical enterprises in Russia

Marketing research of production volumes of pumping equipment in the segment "Water supply and sanitation"

Import/Export Analysis of Glass Making Machinery

Price dynamics for potash fertilizers (FSU FOB) 2006-2013

The average annual growth rate of the market for forged blanks until 2015 in the Russian Federation will be 8-10%.

The average annual growth rate of the forged blanks market in Russia will be 8-10% by 2015.

Study of the demand for generator sets with a unit capacity of 560 - 25,000 kW among Russian companies in various industries.

Marketing research of the traffic control market conditions

Analysis of imports of carbide metal-cutting tools for 2013 in the Russian Federation

Marketing research of freons (freons) market

Butane and isobutane market research

Marketing research of the baddeleyite-corundum refractories market in the glass industry

Marketing research of demand for transformer substations in the Far Eastern Federal District

Export/import analysis

Investments in various industries

Explosive growth of the unmanned aerial vehicles market

In the next 5 years, the annual growth rate of the UAV market will exceed 10%.

White spirit consumption reached pre-crisis level

Recovery of the mineral spirits market.

Marketing research of the market conditions for gas analyzers and other devices for detecting poisonous substances (sarin, soman, etc.)

Marketing research of the Private Label market in Russia

Equipment export/import analysis

Assessment of the feasibility of creating the production of freon 227ea on the premises of JSC "PO" Electrochemical Plant "

Marketing research of unmanned aerial vehicles

Export/Import Analysis: Textile Machinery

Market research of seamless pipes used in heat and nuclear power industry

Promotion of WEG products - electric motors in the oil production segment

Marketing research of the Russian market of metalworking equipment

Market overview of 4 chemical products

Marketing research of the associated petroleum gas equipment market

Updating market research of the associated petroleum gas processing equipment market.

Study of the market of transport services in the Far Eastern Federal District and the Southern Federal District

Marketing research of the equipment market for laminating chipboard panels

Transportation analysis

NGV fuel

CNG consumption in Russia may increase by 1.7 times by 2015.

Marketing research of the equipment market for associated petroleum gas processing

Study of the ability of Russian enterprises to produce cross-cutting and sorting equipment with ...

Marketing research: exporters of the 4th group of TNVED 2012-2013-1p

Marketing research of the high-precision iron casting market

Marketing research on the high-precision iron casting market.

Study of cost distribution for the largest Russian metallurgical enterprises

Export-import analysis: woodworking

Export-import analysis: Europe, Baltic States, Kaliningrad

LNG market research

Potential demand for LNG in Russia can be estimated at more than 1-3 million tons per year.

Export-Import Analysis: Ceramics and Carpets/Fabrics

Analysis of export-import of ceramics, furniture???????

MI of the world and Russian market of hybrid cars

Marketing research on the selection of 30 cities to expand the regional network

Analysis of trade turnover between Russia and China

Marketing research of the market of organosilicon products

Market research of the market by manufacturers of equipment for the production of chipboard in Russia

Marketing research of the market of design and survey services

Marketing research of the market of dry building mixtures

Marketing research of the market of non-insulated flexible wires such as metal (copper) braids (PML, PARML, etc.).

research of publicly available information resources of the venture capital market of the Russian Federation

Research for RVC

Extended LNG Study

Car market research

Research of publicly available information resources of the venture capital market of the Russian Federation

Marketing research of the straw market in the Russian Federation

Research of the world and Russian market of hybrid cars and electric vehicles

The Russian market of equipment for long-term oxygen therapy at home and CPAP therapy

Rubble

The crushed stone market grew by 12% over the last year

Citric and succinic acid

Consumption of citric acid in the Russian Federation increased by 2.4 times over 4 years.

Alkylbenzene

Euro 5 stimulates the development of the alkylate market

Prospects for the Russian railway engineering in terms of the use of cars with aluminum structures

Market overview of metalworking tools in Ukraine

Overview of the metalworking tool market in Ukraine

Marketing research of the construction and elevator market

Russian projects on the production of lysinе

Monitoring of prices and conditions of fiber and optical cable

Current Research April 2013

Current Research

Marketing research of the ductile iron market

Marketing research of the market conditions of consumers of special cable compounds

Updating of marketing research of the market of supercapacitors

Marketing research of the market of food products with a long shelf life of the segment "Premium"

"Azbuka Vkusa" will open 80 stores in the next 5 years.

Glass mesh market

The Russian glass mesh market has exceeded pre-crisis levels.

Analysis of imports of carbide metal cutting tools for 2012

Marketing research of the Russian market of specialty chemical products

Iron casting market in Russia 2010-2011 and prospects for its development until 2015.

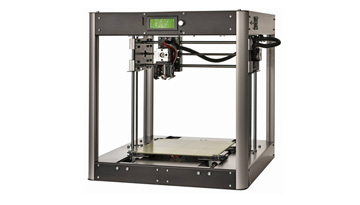

Marketing research of the 3d printer market

Marketing research of the market situation for alkyl gasoline (alkylate)

Updating the finished study on carbon dioxide

Changing the contact phone number

Our new phone number is +7 (495) 777 91 87

Barite

In 2012, supplies of barite ore doubled

Marketing research of crushed stone market conditions

Automotive components market research

Investments in the production of automotive components in Russia exceed $1 billion...

Marketing research of the butane and isobutane market

From 2007 to 2011, butane imports to Russia in tons by main recipients grew 14 times, and in monetary terms – 25 times. Many importers made purchases for the first time in 2011...

Market research of polyethylene pipes

From 2000 to 2010, the Russian polymer pipe market grew sevenfold...

Global mining industry investments in renewable energy and energy conservation will be about $8.4 billion in 2016...

Global mining investments in renewable energy and energy conservation will be about $8.4 billion in 2016...

Development strategy for the pharmaceutical cluster, biotechnology and biomedicine of the Kaluga region

Biopolymers

Over the first decade of the new century, the consumption of plastics has increased by almost 50% ...

Prospects for the Russian market of glass composites

GRP pipes segment demonstrated the highest growth rate. So in 2011 ...

The polyester fiber market in Russia will grow 11 times

Given that polyester threads and fibers are today day the most demanded textile raw material, the volume of the Russian market by 2015 may increase by more than 11 times.

Carbon Dioxide Market Research

Carbon dioxide market research

Russia is waiting for an increase in the market for propylene and polypropylene

Propylene demand will more than quadruple.

Increasing demand for propane-butane

What awaits the Russian motor fuel market?

Conference "LEDs: chips, products, materials, equipment"

Industrial Information Agency participated in the conference "LEDs: chips, products, materials, equipment".

Russia increased the export of liquefied hydrocarbons by 3.5 times

Russia has increased the export of liquefied hydrocarbons by 3.5 times, and demand will soon increase in the domestic market.

LEDs are on the verge of a new phase of growth

Continuous demand for light emitting semiconductors

The Industrial Information Agency conducted an audit of a marketing research on the market for cast iron bathtubs.

Industrial Information Agency conducted an audit of a marketing research on the market for cast iron bathtubs.

What will Russian roads look like in 10 years?

What will Russian roads look like?

Accreditation of Sberbank of Russia

Our Agency is accredited by Sberbank of Russia OJSC

Energy saving in the chemical industry

The largest energy consumers - North America, China and the European Union announced new energy saving plans...

LEDs are on the verge of a new phase of growth

LED production cost will decrease

The Industrial Information Agency conducted an audit of the marketing research of the grain crops market.

Industrial Information Agency conducted an audit of marketing research on the grain market.

Growth of export deliveries of wheat

The traditional importers of Russian wheat are…

New research from API

Recent marketing research.

Transition from asphalt concrete to other surfaces

A smooth transition is planned from asphalt concrete to other pavements

Boom of intellectualization

Intellectual boom is rolling around the world

Production volumes of adhesive additives and emulsifiers by manufacturers

Potassium chloride market research in Germany, Canada, India, Belarus

Potassium chloride market research in Germany, Canada, India, Belarus

API recommends checking it out! Research of the market of "smart settlements"

API recommends check it out! Smart Village Market Research

Study of opportunities of equipment manufacturers for production of OSB-plates in Russia

Study of demand for flux-cored wire and lumpy ferrous material

Metallurgical enterprises modernization in Russia

Analysis “Russian food market for HoReCa. Segment Japanese cuisine»

Research of the World and Russian market of activated carbon

Industrial Information Agency Analysts conducted a Study of the World and Russian market of activated carbon.

Market of metal forgings

Fuel cell market research

Industrial Information Agency Analysts conducted a study of the fuel cell market and the prospects for its development in Russia.

Russia - the leader of the world hydrogen energy?!

Russia is the world's leader in hydrogen energy?!

The share of imported tinplate increased to 54%

The share of imported tinplate increased to 54%

Increasing demand for exhaust gas cleaning agents

The Russian market for exhaust gas cleaning chemicals may increase to 240 million euros.

Import of anionic surfactants increased by almost 3 times

Import of anionic surfactants almost tripled

Creating a cluster based on composite frame house construction in Ingushetia

Russian glass container market

Tinplate market in Russia and the CIS

Evaluation of the market prospects for underfloor heating systems for residential, public and commercial premises

Russian and European market of fuel granules

Russian market of heavy railway castings

Research of the market of large cast steel blanks for hydraulic turbines

Russian market of energy saving glass and glass units

Identifying customers for profile steel pipes in the Middle East and North Africa

Hydrate lime market review (2008 - 1st half of 2010)

Study of the global market of non-nuclear zirconium

Market research of a key component of energy-saving lamps

Research Completed: Market Overview of a Key Component of Energy Saving Lamps: electronic ballasts

Market Research for Hybrid Vehicles and Electric Vehicles

Projects completed: «Marketing research of the hybrid car market and electric vehicles" and "Market Study for Charging Stations for Electric Vehicles and Hybrid Vehicles".

Overview of the market of straight welded pipes in the Russian federation (the possibility of their application in the fuel and energy complex)

World and Russian market of solar cells

Our analysts conducted a marketing research: "World and Russian market of solar cells"

Prospects for shale gas production

Analysts are completing a study of the shale gas market.

Marketing research of the market of energy-saving lamps

Completed work on the project: "Marketing research of the market of energy-saving lamps".

Marketing research of the market of LED lamps

Analysts conducted a marketing research of the LED lamps market, which includes not only analytical data, but surveys of market participants.

Marketing research of the associated petroleum gas market

Completed Project: "Associated Petroleum Gas Market in Russia and the CIS"