Market assessment (who is the consumer, service provider (equipment), market volumes) in the following areas of additive technologies:

1. Quick prototyping, small -scale production and production preparation:

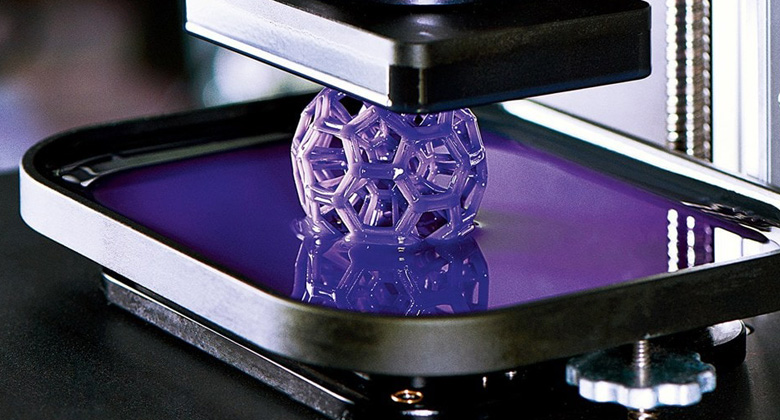

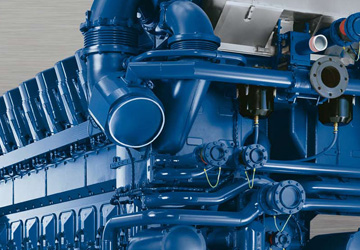

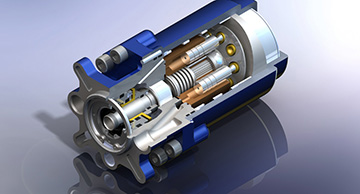

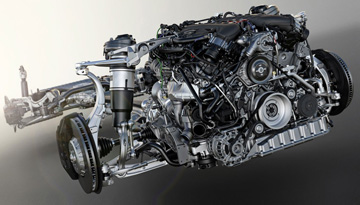

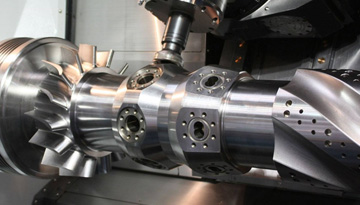

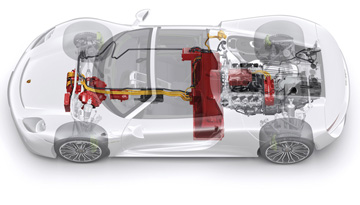

- manufacturing by the additive method of prototypes of products and layouts of any geometric complexity and internal structure from various materials;

- manufacture of smelted or burned models for precise casting of metals;

- rapid production of prototypes and small parties of plastic products by vacuum casting in silicone forms;

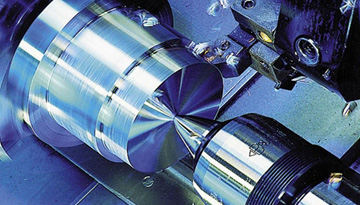

- design and manufacture using SLM technology of special press forms and inserts for thermoplastavtomata;

- Production of products from metals and composite materials by additive technology (SLM, SLS, SLA).

2. 3D scanning (including reverse engineering):

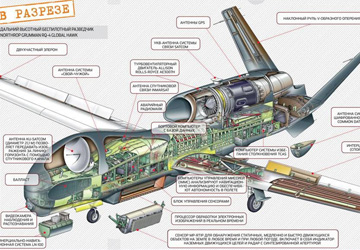

- 3D scan of objects;

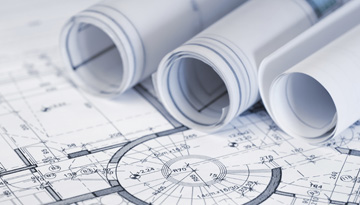

- obtaining parametric models based on scanning data;

- control of geometry and size (verification) with the issuance of a report;

- Development of design documentation on the basis of a 3D model.

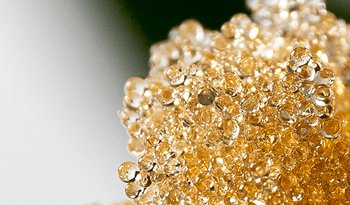

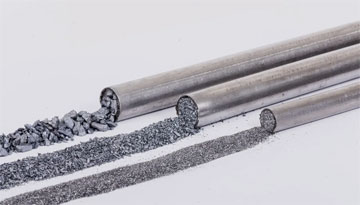

3. Conducting research on the development of technology for the manufacture of parts from metal powders and composite materials:

- search for optimal fusion or sintering modes to obtain the most dense structure;

- research and testing of the obtained samples;

- research and testing of consumables;

- standardization and certification.

4. Organization of training or advanced training in various areas:

- Fundamentals of 3D scanning;

-optimization of 3D models, preparation for 3D printing;

- operation of 3D printing systems (metal and polymers).

5. The supply of equipment with waste technologies to solve the production problems of the customer company:

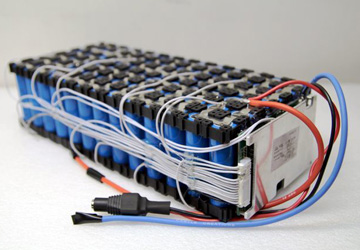

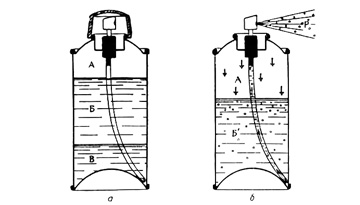

- additive production systems;

-systems of 3D scan and 3D measurements;

- delivery, commissioning, training, warranty and post warranty service.

6. Supply of consumables:

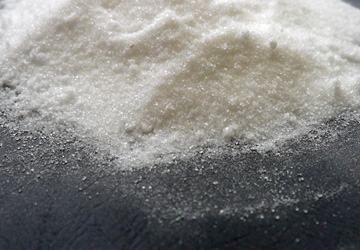

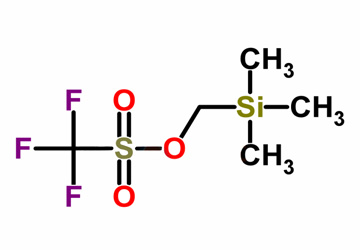

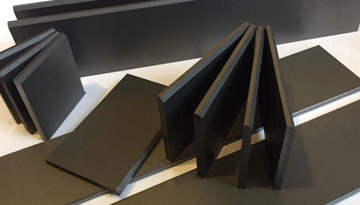

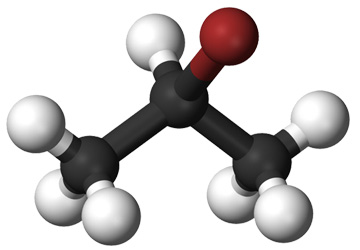

- metal powders for additive production systems obtained by various methods;

- composite powder materials for systems operating using SLS technology;

- photopolymers with various properties (burned, heat -resistant, ABS similar, etc.) for systems operating according to SLA technology;

- plastics and composite materials for systems operating according to FDM technology;

- Photopolymers for systems operating using MJM technology.

7. Post -cutting parts obtained by additive technologies:

- high -temperature;

- gas static;

- Vacuum thermal.