Segments

1. Self -propelled career equipment for mining enterprises and construction equipment

2. Self -propelled career equipment (dump trucks)

3. Burial and passing vehicles

4. Crushing-flair equipment

5. other equipment

The commodity boundaries of segments:

According to the segment "self -propelled career technique"

For mining

Career excavators

Cable electric excavators

Hydraulic excavators with a working mass of 60-120 t

Hydraulic excavators with a working mass 150-1200 t

Draglays

Rotor excavators

Excavators are chain

Wheel front loaders for quarries with a bucket of more than 8-35 m3 weighing more than 35 tons

Caterpillar bulldozers with a capacity of 400-1200 hp

Wheel bulldozers

Loading and rental vehicles shaft

Loading machines

Combines are treatment

Construction equipment

Hydraulic excavators on the caterpillar

Hydraulic excavators on a tracked course weighing 14-60 tons;

Hydraulic excavators on a caterpillar from 0-13 tons (mini/midi)

Hydraulic excavators on the airborne

Pontone excavators

Excavators on the railway platform

Excavators based on trucks

Installations with vibration loaders at the caterpillar base

Wheel front loaders with a bucket up to 2 m3

Wheel front loaders with bucket 2-7 m3

Excavator loaders

Dragging with telescopic arrow

Caterpillar loaders

Wheel loaders

Self -propelled lifts

Bulldozers with a capacity of 60-400 hp

According to the segment "self -propelled career technique (dump trucks)"

Hinged dump trucks with a carrying capacity of up to 60t

Career dump trucks

Continuous career combines

Career dump trucks with a hard frame with a load capacity of 30-95 tons

Career dump trucks with a hard frame with a carrying capacity of 120-360 tons

Career dump trucks based on road trucks

Self -sides on the caterpillar

Underground dump trucks

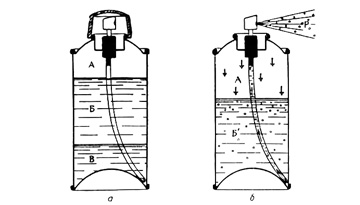

According to the segment "Burial and passing machines"

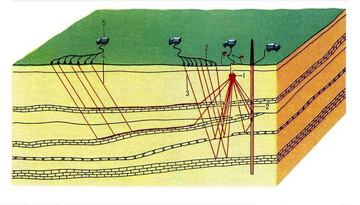

Drilling machines for drilling explosive wells on quarries

Barrow drilling machines Electric

Hyro -shaped brown -shaped drilling machines

Drilling machines with hydraulus

Drilling pneumatic pneumatic drilling machines

Machines for geological and geotechnical drilling

Labbators and overloaders

Underground drilling installations

Slopes drilling

Use installations for deep explosive wells

Complex vertical drilling drilling installations (type Robbinson)

Drill-crown machines with a carrying capacity of 20-200t

Drilling plants with a torque of 100-500 kN

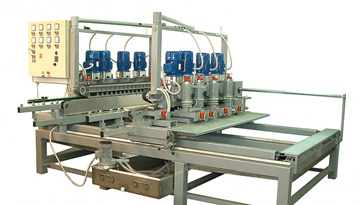

According to the segment "crushing-flair equipment"

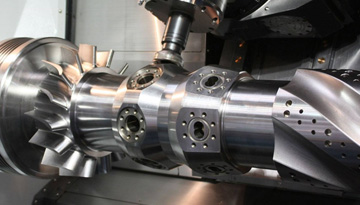

Crushers

Drill crushers

Drowning crushers are mobile

Crushes are stationary cheek

Menous crushers

Mobbile crushers are mobile

Crushes are conical stationary

Rotor crushers

Meners are hammers

Walk crushers

Shock-center crushers

Roar

Mills

Millings are drum balls

Mills are core

Millings of self -insight

According to the segment "other equipment"

Conveyors

Steppe are mechanized

Self -propelled wagons

Anchorostaners

Tunnel -extension units

Feeders

Washing installations

Overloaders (metallol and so on)

Pipe layers

Graders

Scraper

Preliminary contents of the report.

1. Information on each segment

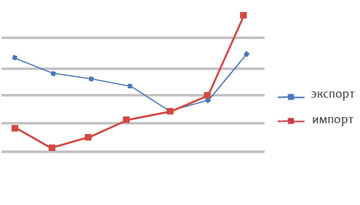

1.1. The total volume of import imports for 2011-2014.

1.2. The structure of imports in the context of the type of technology (see table) 2011-2014.

1.3. For each type of imported technology, the following information will be presented:

The main manufacturers,

prices,

Recipients

Technical characteristics of the main brands

1.4. The list of Russian manufacturers for each type of equipment (declared data of companies)

1.5. The most scarce (insufficient level of Russian production) /sought -after positions among Russian consumers

2. Analysis, conclusions

2.1. The rating of the attractiveness of segments (scale, dynamics)

2.2. The most promising positions in each segment in terms of import substitution

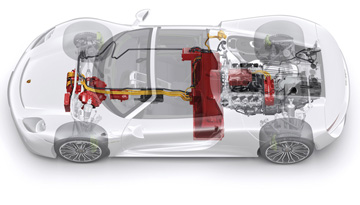

2.3. The possibility of standing positions within the framework of one manufacturer (on the example of foreign companies)

2.4. The most promising positions among all segments for organizing production in Russia