Research segments:

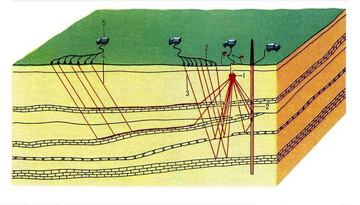

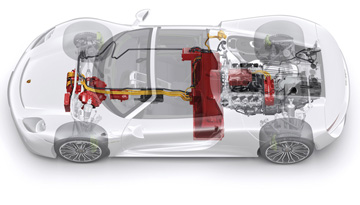

- Geological exploration

- Oil Production

- Oil transportation

- Oil refining

- Transportation of oil products

- Oil depot

- Gas station

Research tasks - stage 1:

1.1. Determination of types (types) of containers according to the purpose used in these segments (for storing drinking water, for storing water for fire extinguishing needs, etc.)

1.2. Determination for each type (types) of the capacities of key characteristics: position (vertical/horizontal, underground/aboveground); volume, for elk - power and degree of cleaning.

1.3. The current requirements for each dedicated type (type) of equipment.

1.4. The most popular products (containers, los) in each of the selected types (types) of containers, taking into account their key characteristics.

1.5. Determining prices for the most popular products, as well as for products with minimal, medium and maximum capacity (m³)

Research tasks - stage 2

2.1. The selection of containers and elk are of interest to the customer according to the results of stage 1.

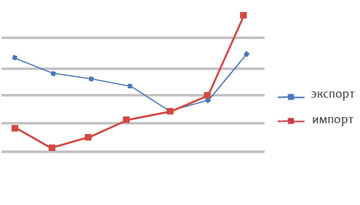

2.2. Assessment of the real volume of consumption of selected products

2.3. Consumption forecast until 2015 of selected products

List of tanks and containers

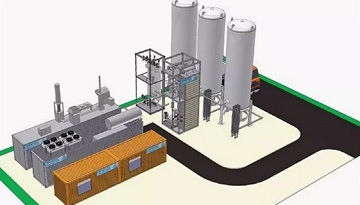

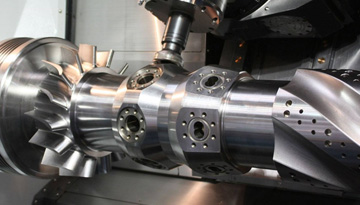

Oil production (containers and tanks for various appointments)

According to the "List of Technological Equipment of Objects of the Basic Production of Oil Field Arrangements, which is to be placed in open areas" The following types of containers are established at oil industrial enterprises:

1. Collection and transport of oil, gas and water

1.1. Underground horizontal drainage containers

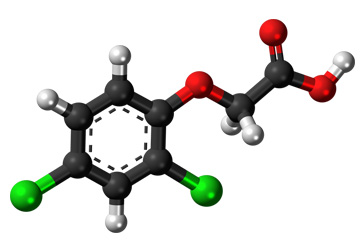

1.2. Containers for storing chemical reagents that are not freezing at low temperatures

1.3. Tanks for storing oil and oil products (metal)

1.4. Purge containers (equipment for purging gas pipelines)

2. Preparation of oil

2.1. Sumps of preliminary and deep dehydration type OG-200S

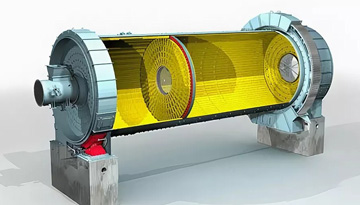

2.2. Electro dehydrators

2.3. DEMULSTERS type UDO and DG

3. Gas preparation

3.1. Condensate collection containers

3.2. Oil containers

4. Factory of oil strata, water supply and sewage

4.1. Technological capacity for water BKNS

4.2. Capacitance expansion of the circulating system of water supply

4.3. Fire reserve tanks

4.4. The reservoirs of a solution of the foaming agent

4.5. Ranks of flushing water

4.6. Water containers with submersible pumps

4.7. Tanks and blocks of sumps (BO), horizontal and vertical

4.8. Spotoric blocks with a coales -cycle filter (OKF)

4.9. Social tank tanks buffer and regulatory containers

4.10. Ouscaum tanks with hydrophobic filter pressure

4.11. Called oil reservoirs

4.12. Containers for storing chemical reagents, non -freezing and non -surviving at low temperatures

4.13. Bucky decarbonized water, condensate

5. Heat supply and ventilation

5.1. Metallic tanks for storing fuel oil

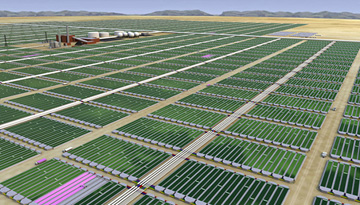

Oil refining (only tanks included in water supply and water treatment systems)

According to the "departmental instructions for the technological design of industrial water supply, sewage and wastewater cleaning of the oil refinery enterprises", enterprises should include:

Water supply systems:

1. The first water supply system - for devices that cool or condensing products, which, with a normal or emergency state at atmospheric pressure, are in a liquid state;

2. The second water supply system - for devices that cool or condensing products, which, with a normal or emergency condition with atmospheric pressure, are in a gaseous state;

3. The second "A" system of water supply-for capacitors of steam turbines of the LK-6U plants and is released into an independent turnover cycle;

4. The fourth water supply system - for devices in which pollution of cooling water is possible by paraffin and fatty acids;

5. Separate special revolving cycles for production with specific substances that can pollute the revolutionary water (sulfuric acid, oleum, etc.), or for production requiring a drop water of a certain quality.

Supporting systems

6. The first sewage system-for the dash and cleaning of production-orch wastewater. These wastewater after cleaning are used to replenish the current systems and water supply to individual consumers of the enterprise.

7. The second sewage system - for the disposal and cleaning of emulsion and chemical wastewater, contaminated with oil products, reagents, salts and other organic and inorganic substances (eloe drainage, sulfur -base, trinemic waters of raw materials, salt -containing drains from blowing boilers - recycled and other. .). After the drainage of the second sewage system is cleaned, if they cannot be used in production, they are sent to the dialing with the subsequent discharge into the reservoirs, provided that the requirements of the "rules for protecting surface water from pollution of wastewater".

8. The third sewage system is provided for the collection and rescue of surface runoff (rain and talus) from the undeveloped territories of the enterprise.

9. The fourth system of sewage system is provided for the disposal and cleaning of household wastewater from sanitary units of production, administrative and household premises.

Wastewater treatment systems

The following complexes of treatment facilities are used to clean production wastewater in the first and second sewage systems:

10. Local cleaning that is part of the technological installations for drains contaminated with specific substances;

11. Separate mechanical and physico-chemical cleaning for wastewater of the first and second sewage systems; The composition of the structures of mechanical and physico-chemical cleaning includes the following structures:

- Livnesbros - for wastewater flow into an emergency container, with a consumption of them, exceeding the calculated during the rain or in the case of a tank for the tank with oil products;

- emergency container - for receiving excess wastewater or oil products

- sandbags - to detain gross mineral impurities and collecting floating oil products;

- hydrocyclones open (non -pressure) - to detain gross mineral impurities;

- Oilovushki - to capture the bulk of oil products and mechanical impurities;

- radial sumps - for the separation of pop -up oil products and besieging suspensions, as well as averaging the composition of wastewater and capturing possible volley passes of oil products from oil flows (are currently used only in the reconstruction of existing enterprises);

- The installation of reagent pressure flotation is designed to remove thin -eomulgated oil products and colloidal particles from wastewater, as well as for partial removal of organic compounds dissolved in water.

12. Separate biochemical cleaning of wastewater of the first and second sewage systems;

13. Domination of biochemically purified wastewater; The treatment of biochemically purified wastewater of the first and second sewage systems is also carried out separately.

14. deep cleaning of wastewater dumped into a reservoir;

15. dehydration of captured petroleum products;

16. Processing of oil and excessive active silt.