1 subject of services

Consulting services (hereinafter referred to as the services), which are provided for by this technical task, suggest an assessment of the forecast for the demand for products by business units (procurement industries) (hereinafter-SP) in the horizon of 2019-2030 ..

2. The purpose of the provision of services

The aim of the provision of services is a comprehensive assessment of the capabilities (prospects), the risks of the project and confirmation of sales volumes in accordance with the current volumes of production and sales of products for the use of this information stated by the customer as a justification for the subsequent decision on the participation of the bank in financing the project.

3. Terms and definitions

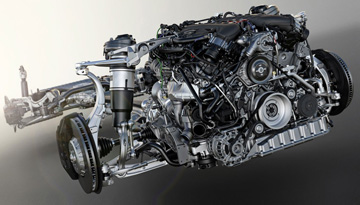

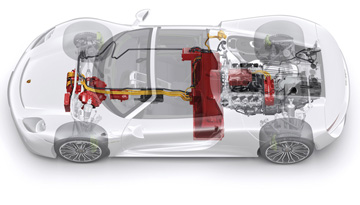

Products are components for customer cars and other products produced by ZP for external markets.

4. The subject of the study

4.1 for blacksmithing:

Current nomenclature:

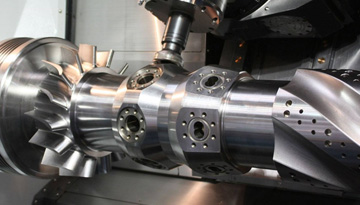

Stamped blanks designed for the manufacture of parts of the automotive industry, in particular:

Stamped blanks weighing from 0.5 to 25 kg, obtained by hot volumetric stamping (GOSH) on curved hotstam -stamping presses (KGSHP) with an effort from 1000s to 6300s;

- stamped blanks weighing from 0.5 to 25 kg, obtained by hot planting on horizontal-captive machines (GKM);

- stamped workpieces weighing from 50 to 110 kg, obtained gosh on specialized crankshaft lines and front axle beams (BPO);

- blanks weighing from 0.5 to 20 kg, obtained on other KZ equipment (PKP, RKM, and a/line of flexible shutters of the flywheel, hot -shaped automatic machine "Hatebur", etc.);

The nomenclature planned for the customer and external consumers (starting from 2020):

-for own consumption ~ 95-130 thousand tons of generations;

- For the external market - at least 14-18 thousand tons of generations.

Stamped blanks designed for the manufacture of parts of automobile, oil and mining industries, in particular:

- stamped workpieces weighing from 1.0 to 45 kg, obtained by hot volumetric stamping (GOSH) on crooked hot -stamping presses (KGSHP) with an effort from 1000s to 8000s;

- stamped workpieces weighing from 0.5 to 35 kg, obtained by hot planting on horizontal-shells (GKM);

- blanks weighing from 0.5 to 20 kg, obtained on other KZ equipment (PKP, RKM, and a/line of flexible shutters of the flywheel, hot -shaped automatic machine "Hatebur", etc.).

4.2 for stamping production:

- Current nomenclature:

- by the method of cold stamping, the crossbars of the frame, brake pads, parts of fuel tanks, parts of silencers, air cylinders, mortgage reinforcement, cabins and cabin plumes are made;

- the production of the beam of the crankcase of the leading bridges is carried out by the method of hot stamping;

- small, medium, large stamps, control devices, models

(starting from 2020 g):

-for own consumption ~ 85-112 thousand tons of stamping, including 40-52 thousand tons are large and 45-60 thousand tons of medium;

- for the external market - at least 135-180 thousand tons of stamping, including 90-120 thousand tons are large and 45-60 thousand tons of medium.

4.3 for foundry:

Current nomenclature:

- cast iron castings (casting in sandy - clay mixtures)

- Material brand: account 18, 21, 25, HF 40.45.50.60 according to GOST RF 1412-85, GG 15,20,25, GGG 40.50.60 according to DIN 1691.1693 (Germany), mass, mass, mass kg min 0.200 max 350.0

- cylinder blocks, monoblocks, flywheels, hubs, cylinder heads, hubs, brackets, pads, crankshaft shafts

- Paces made of steel (casting in sand and clay mixtures)

- Material brand: became cinema casting, heat -resistant, heat -resistant, wear -resistant, mass, kg min 0.4 max 200.0

- Carters, swing fist, brake caliper, supports, brackets, levers

- castings from aluminum alloys:

- casting under pressure - mass, kg min 0.013 max 6.2

- casting under low pressure - mass, kg min 1.0 max 25

- in Kokil - mass, kg min 0.300 max 11,

- casting from zinc alloys under pressure

- mass, kg min 0.008 max 1.3

- Casting in technology "AutoForge"

- mass, kg min 0.030 max 0.500

- continuous casting of pipe from brass and bronze: dimensional characteristics:

A section with a diameter of 25 to 185 mm up to 3000 mm long

Promising products (starting from 2020):

-for own consumption ~ 85-110 thousand tons of cast-iron casting and ~ 20-25 thousand tons of steel casting;

-For the external market-at least 45-55 thousand tons of cast-iron casting and 10-13 thousand tons of steel casting.

Cast iron castings: cylinder blocks, monoblocks, flywheels, hubs, cylinder heads, hubs, brackets, pads, shafts crankshaft

Steel castings: crankcases, swing fist, brake caliper, supports, brackets, levers

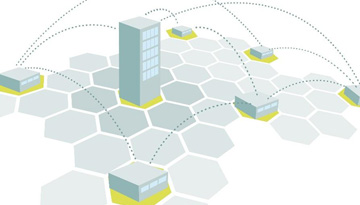

5. Geography of the study

For the study of manufacturers of similar products: Germany, Japan, France, Italy, Turkey, China, USA.

For studying the demand for manufactured products for the external market (in priority):

- India, China,

- CIS countries, Russia;

- Asian market;

- European market;

6. Study period

Actual data from 2011 to 2013 (inclusive).

Market development forecast until 2030

7. Composition and content

- In the marketing study of the market for products, the following sections should be included:

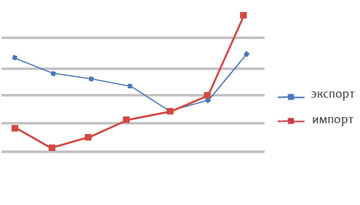

- Information on the historical data of the balance of supply and demand on the market for the presence of products in the context of buyers and sellers;

- Description of factors affecting the balance of demand and proposals in the market for the presence of products;

- Forecast for the balance of supply and supply market in the market in the context of buyers and sellers;

- Analysis of potential buyers (client base), bringing a comparative qualitative and quantitative characteristics of products of products with consumers of analogues/competitors based on available data from open sources, including paid;

- Comparative analysis of products for products (current price level, for the forecasting period);

- Assessment of the relevance and competitiveness of the price parameters indicated in the project planned for production;

- A comparative analysis of competitiveness (including technical and operational characteristics) of products, its competitive advantages / disadvantages;

- Quantitative assessments of the influence of factors on growth/reduction of demand on products in the context of buyers and sellers;

- Assessment of the volume and structure of supplies to the domestic and external market:

- Assessment of supplies (in natural and value terms);

- Analysis of the geographical structure of supplies;

- Analysis of competitors' proposals for similar products;

- In export - what are significant competitive advantages of the products of foreign competitors, the difference in consumer preferences in the importing country is possible;

- Characteristics of the level of consumption and basic trends;

- Assessment of the market potential to the level of saturation (including determining the stage of the life cycle of the market), given the data on the world market.

- Promising market niches for procurement industries (indicating the nomenclature taking into account technical restrictions on procurement industries).

- The capacity of the niche

- competitive price level

- a forecast for the development of a competitive environment by niche

- Dossier on leading competitors of procurement industries in the context of regions (RF, China, India, USA, Germany, Korea, Turkey, etc.):

- Scenario forecast-analytical assessment of the dynamics of the maximum sales volume of products in relation to various external and internal conditions, taking into account the factors of its technical and price competitiveness;

- A description of technological improvements (technical characteristics) that are necessary to maintain the competitiveness of products to ensure various scenarios in terms of sales of cars, taking into account the terms of the necessary modernizations;

- Analysis of the cost of production in comparison with the main competitors in the presence markets;

- SWOT analysis, as well as the classification and analysis of key marketing risks of the project, an expert assessment of the likelihood of key risks, quantitative analysis of the potential consequences of risk implementation, development of measures to minimize key risks;

- Analysis of the influence of state support measures (including compensation for losses and others) on the implementation of the project, including the effect of support measures on the cost and possibility of sales of products (the section must contain both qualitative and quantitative assessment);

- Analysis of the project marketing strategy, recommendations for achieving the volume of products sufficient for the payback of the project;

- A map of key marketing risks of the project, an expert assessment of the likelihood of their onset, a quantitative analysis of the potential consequences of risk implementation and a set of measures to minimize them;

- Recommendations to increase the sales of products sufficient for the payback of the project including recommendations on the marketing strategy (target markets, customers and offer).